Tips and Advice

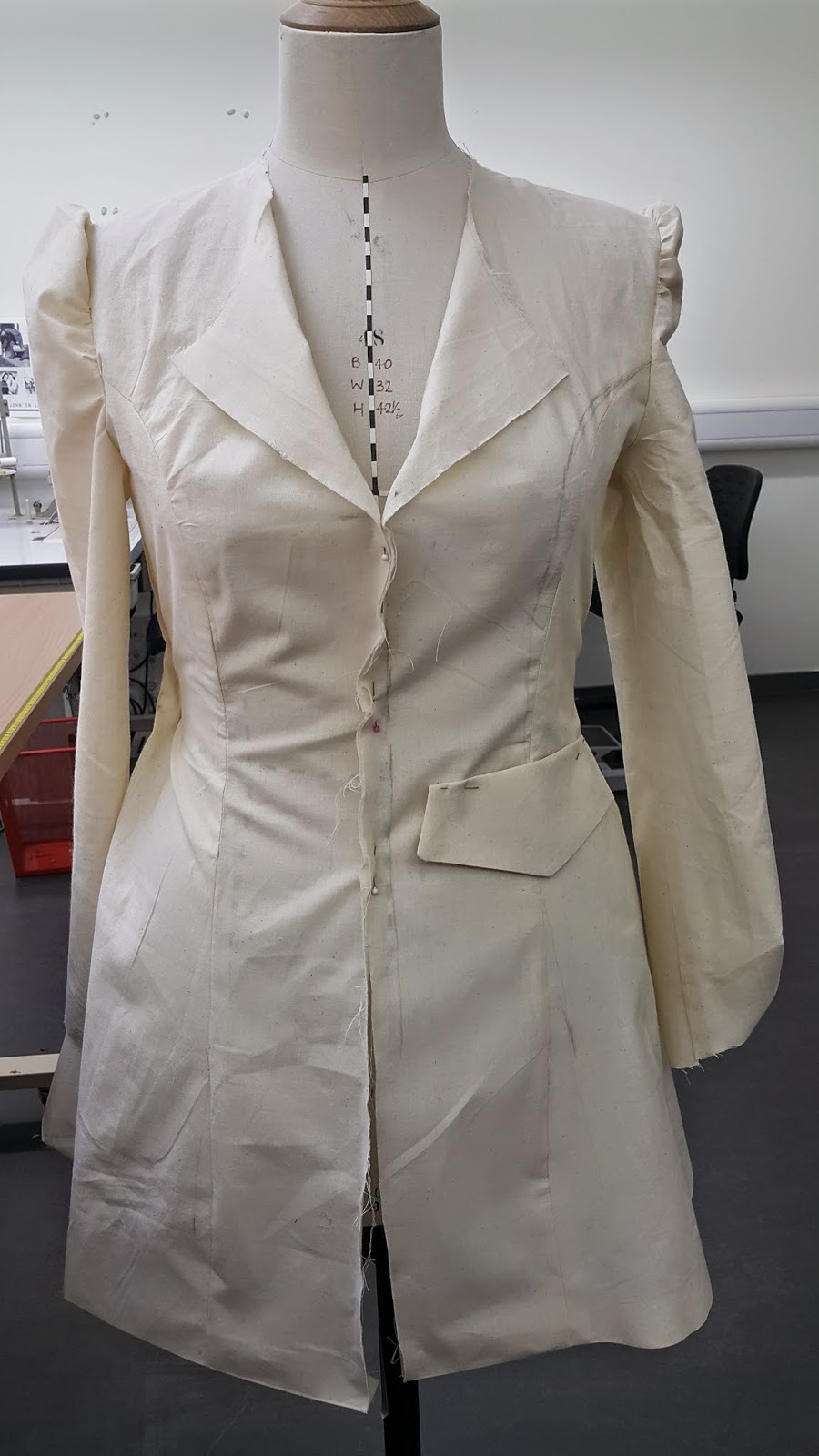

- Longer front than back and sides. Back should still cover all shirt showing no trouser gap at the back.

- Uneven number of buttons 5 for men under 6 foot and 7 for over. Stops large gap or fabric inbetween.

- Try waistcoat with jacket to check the v line and shirt to check neck line for gaping. Neck line should sit neatly around the neck and under the collar so it doesn't sit away.

http://welldresseddad.com/2013/12/31/the-waistcoat-project-the-first-effort/

http://fabric8online.blogspot.co.uk/2012/11/making-waistcoat-and-adding-functional.html